2. Forming process of rectangular tube

Rectangular tube can be divided into two types, direct forming process, namely, "square to square" (directly to square) and "round to square" (from circular tube to rectangular tube). Many documents compare the characteristics of the two processes. The production enterprises also adopt different processes according to the equipment condition. CCRSA held the Direct Forming Technology of Cold-formed Rectangular Steel Tube Symposium in Tai'an, Shandong on 28-29 July 2006.

2.1 The comparison between "round to square" and "square to square".

Many books and documents illustrate the design method of welded pipe and rectangular tube, so we mainly compare the different methods used in continuous roller forming process.

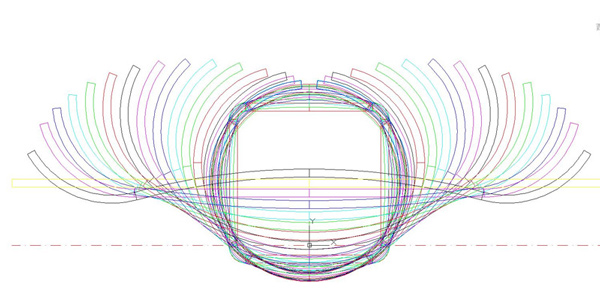

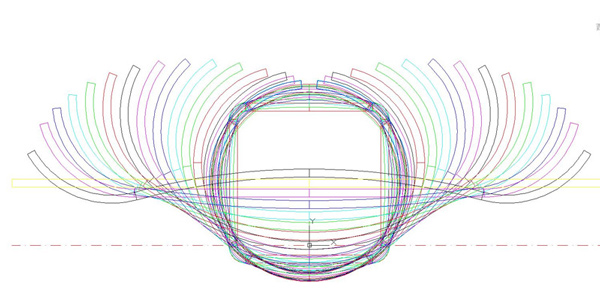

(1) "round to square" forming

The strip steel is formed and welded into a round pipe by the welding mill, and then it is formed into the rectangular tube by the setting machine. By using the “round to square” technology, the strip steel can be first welded into a circular pipe by the circular tube forming equipment, and then be changed into a rectangular tube in the sizing process. For the original pipe welding production line, the investment is small and it is easy to operate. The process is easier to control than the direct forming.

the-roller-technical-drawing-of-round-to-square

Fig. 1. the roller technical drawing of "round to square" (using the immovability of barycenter and downhill method).

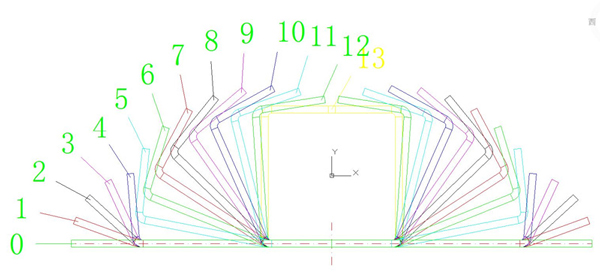

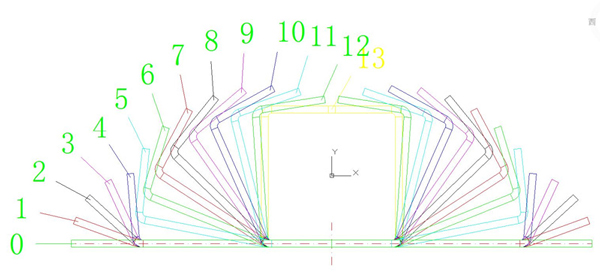

(2) direct forming

The strip steel is directly bent into rectangular tube and then be welded and formed.

Fig. 2. the roller technical drawing of direct forming (without downhill method)

2.2 Advantages of direct forming process.

Compared to "round to square" process, direct forming process has the following advantages:

(1) The roller is made up of roller sheets, which has strong commonality and few roll parts.

By using the direct forming process to produce rectangular tubes, deformation in the round forming stage needs a few sets of forming rollers, it is time-consuming with less efficiency and has high cost. According to the statistics, compared to the "round to square" process, direct forming process can save 50% of the roll cost, reduce the time of changing roll by 40%, increase the production capacity by 15%, and greatly reduce the production cost.

(2) The expansion width of the strip steel is small and the material is saved.

The rectangular tube with the same specification is produced by direct forming process, which can save steel consumption with the smaller strip width. According to the statistical data of the width of the strip for 80×80mm~180×180mm rectangular tubes with different wall thickness produced by foreign manufacturers, the average reduction of the billet of the direct forming process is 2.4% than that of "round to square" process. This indicates that the direct forming process has better economic benefits under certain specifications.

(3) Small forming force and low energy consumption.

The load of the machine set is low when it is directly formed, especially the load of the set is obviously lower than that of the circular tube forming equipment. Intuitively, the two forming methods have the same shape of the strip steel initially and the same geometrical shape finally. The deformed parts of the direct forming process are the four corners of the rectangular tube, but the deformed parts of the "round to square" process are straight edges except the four corners. The edges are formed into rounded edges and then into straight edges. Obviously, some unnecessary deformation processes are added, and the energy consumption of the deformation is increased. Therefore, compared to the "round to square" process, the deformation power of the direct forming process is lower.

2.3 Common problems and countermeasures of direct forming process.

(1) It is difficult to control the welding quality and the welding speed is low when producing steel pipes with the thickness above 10mm.

To meet the requirements of direct forming process, the process of abutting joint, looping, milling and cutting should be adjusted to the production speed. When the welding speed is slow, the quality of the welding is difficult to guarantee. For the product with the thickness above 12 mm, the end shape of the steel strip should be flat. If the end shape is V shaped, the temperature of the lower corner will be high, the burr will be drop-shaped, the welding line will be overheated, the grain will grow and the temperature of the upper corner will be too low to weld. It is recommended to choose solid state high frequency welding. The milling process of the front part of thick products is very necessary.

(2) The corner of the rectangular steel tube cracks when producing high strength steel.

The rectangular tube produced by the direct forming process, if the forming of each corner of the section is generally regarded as the pure bending of the plate, and the outer plate of the neutral layer is stretched, the tensile strain of outermost layer will not produce cracks as long as it does not exceed the elongation of the material. With the increase of strength, the elongation of ordinary materials decreases significantly. As for the high strength steel pipe, whether the direct forming process can be used directly depends on the elongation of the material and the maximum tensile strain of the outer material of the corner.

The angle of rectangular steel tube is formed by the circular arc body corresponding to the circular tube in a closed cavity when using the “round to square” process. The pass design can assign a certain amount of compression to the entity, thus it can significantly reduce the tension on the outside of the round angle and reduce the external crack on the high strength pipe.

(3) The unevenness of the four rounded angles.

The main causes of this problem: A, the distributing in the forming process is unreasonable, B, the design of extrusion side hole is defective, C, empty bending (i.e., blind angle of deformation). In order to optimize the forming angle and order of two bending angles, it is reasonable to reduce the empty bending angle to the maximum of the roll, reduce the blind angle by the reverse bending, apply the side vertical roll, the inclined roll and the core, and select the suitable bending forming method, which all can effectively reduce the unevenness of the rounded angles.

(4) It is easy to produce abrasions on the surface of steel tube.

Whether the structural parameters of the unit are reasonable, the gear speed ratio of the upper and lower rollers, the rational design of the roll structure and parameters, the material and heat treatment hardness of the roll, and the lubrication and cooling will affect the surface abrasion.

The structural parameters of the unit should be able to meet the requirement of the minimum downside strain to provide adequate downhill adjustment. The difference of speed caused by different diameters should be considered according to the linear speed of the system when designing rolls. Use movable rolls when necessary.