|

Name |

Unit |

Qty |

|

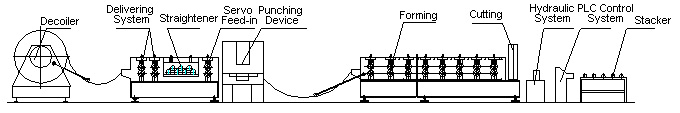

Main Roll Forming Machine |

Set |

1 |

|

Manual Coiler |

Set |

1 |

|

Feeding & Leveling |

Set |

1 |

|

Control System |

Set |

1 |

|

Shear Device |

Set |

1 |

|

Output Table |

Set |

1 |

|

Product Name |

Item |

Description |

|

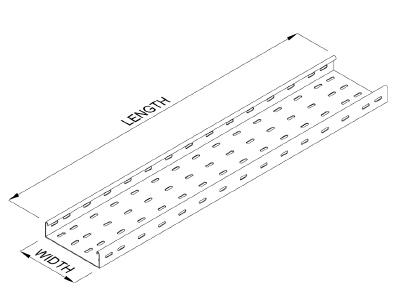

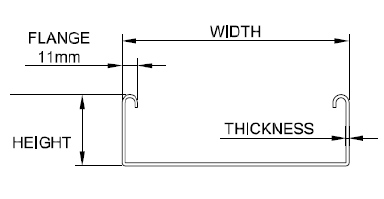

Cable Tray Roll Forming Machine |

Production Material |

Thickness 1.0-2.0mm, structural steel |

|

Forming speed |

15 m/min |

|

|

Number of stations |

15 stations |

|

|

Number of straightening rollers |

7 rollers |

|

|

Number of delivering stations |

2 stations |

|

|

Main motor power |

15.0KW |

|

|

Power of hydraulic station |

5.5 KW |

|

|

Roller material |

GCr15 with heat treatment |

|

|

Shaft diameter |

80mm |

|

|

Shaft material |

JIS S45Csteel quenched |

|

|

Servo motor power for delivering |

3.0KW |

|

|

Punching machine capacity |

100-200T (depending on real needs) |

|

|

Punching system |

High-speed punching automatically |

|

|

Electronic controlling system |

Full-frequency PLC controlling system, |

|

|

Cutting |

Hydraulic cutting after formed |

we will contact you within 24 hours.