4. Key Technologies of Square Rectangular Tube and Prospect on New Technologies

4.1 CAD/CAE technology for square rectangular tube forming

Roll design of the square rectangular tube cold bending forming is one of the key technologies in production. With the computer-aided design technology, the optimal design of the roll with high accuracy and complex profile can be realized. Shorten the design period of the roll and reduce the cost of manufacturing and debugging to make the molding design of square rectangular tube no longer be a trial-and-error method that mainly depends on the experience of the designer and relies on the adjustment and correction.

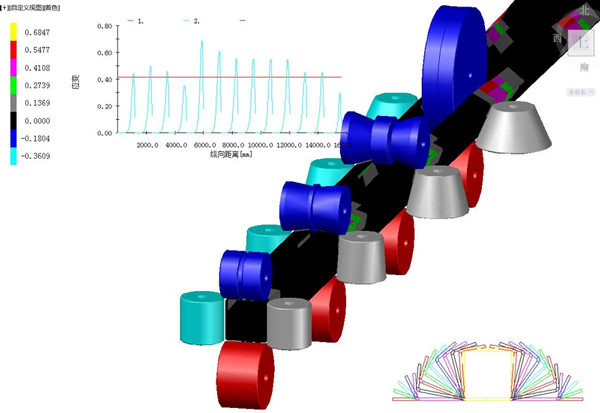

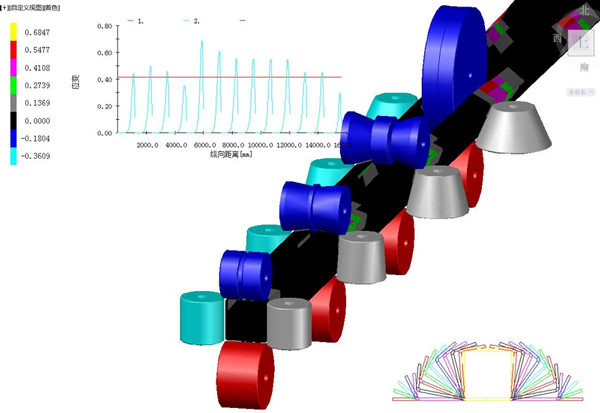

COPRA RF is a professional cold bending forming design software. Jia Leng Company has purchased 2 sets of COPRA RF and has realized the computerization of square rectangular tube design. From processing design and roll configuration to cost accounting and automatic drawing, all design phases can be done by the software. It not only improves design efficiency, but also has many functions that human can not do. Figure 3 is an example of the design of a 200X200 square tube.

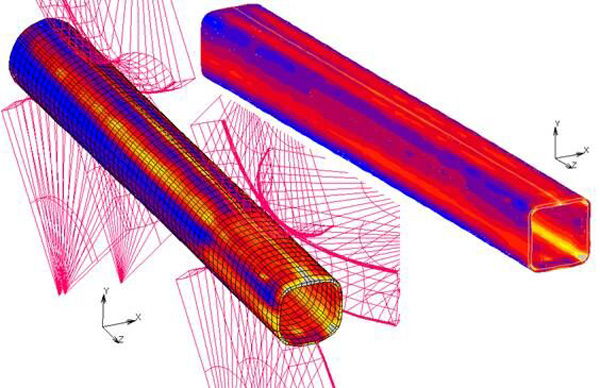

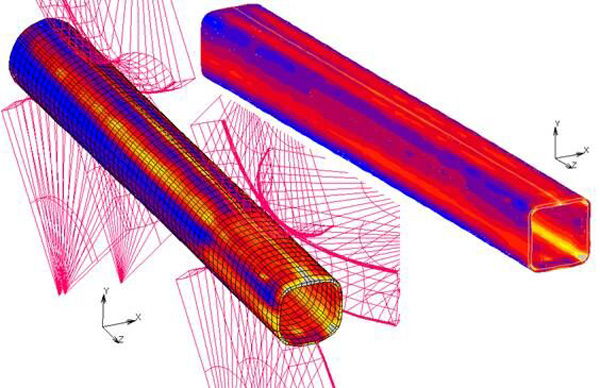

The development of new products of the traditional square rectangular tube depends on the design experience of engineers, and the process of product debugging is essential. Many problems need to be found and corrected during debugging. The use of finite element simulation technology (e.g. COPRA FEA RF) can provide rapid and economical means for product development. The designed roll and strip material can be quickly introduced into the finite element model. According to the actual parameters of the unit, the load of the unit can be calculated, and the vivid simulation result of the molding result can be given. Before the roll is put into production, it can be optimized in the computer to solve the problems that may arise in the design. This allows the debugging process to be completed “ on the computer ”. In particular, the analysis results of some difficult section designs and new materials can be obtained by finite element simulation. Figure 4 is a FEA simulation diagram of a square rectangular tube. Famous cold bending enterprises abroad have basically realized the wide application of CAD/CAE technology.

cad-design-of-direct-conversion-into-square-tube

Figure 3 CAD Design of Direct Conversion into Square Tube

copra-fea-rf-simulation-analysis-of-square-tube

Figure 4 COPRA FEA RF Simulation Analysis of Square Tube

4.2 Forming Technology of High Precision Square Rectangular Tube