4.3 Flexible Forming Technology of Square Rectangular Tube

Adopting the direct forming technology of square rectangular tubes can easily realize the public use of rollers and flexibly adjust the products with different specifications. On the basis of the direct forming technology, a new type unit that applies to the direct forming technology of square rectangular tubes has been developed by equipment manufacturers such as FD Machinery Co.,Ltd. in Dalian.

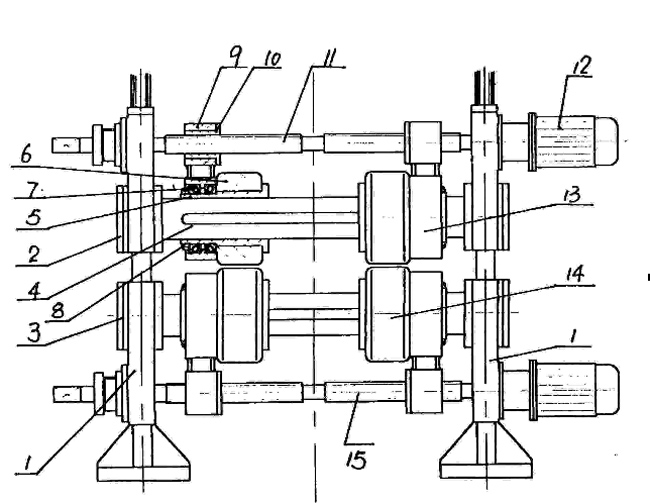

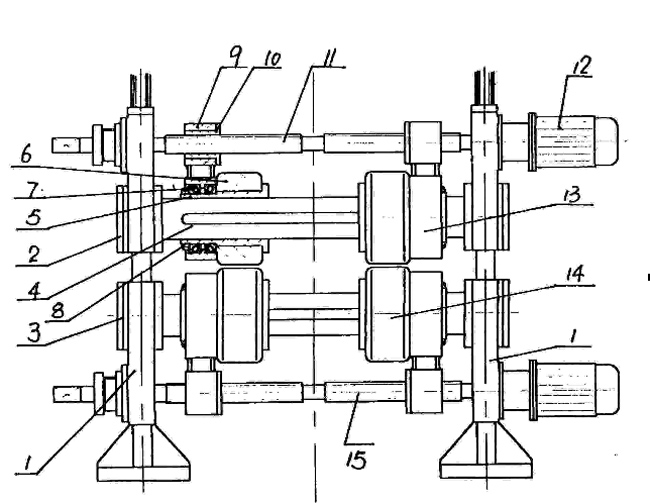

The patent of a kind of section material forming machine has been publicized, this kind of machine includes the organic frame, roll and adjusting mechanism. The frame is vertical. The adjustment mechanism is mounted on the top and bottom of the frame for the horizontal movement of two lead screws. The motor is installed at one end of the lead screw. The upper and lower rolls are arranged in turn and are movably installed on the frame, in the middle of the two lead screws. The ends of the roller are respectively installed with sliding seats, and the upper and lower rollers are respectively fixedly connected with the upper and lower screws. The sliding key shaft sleeve of the two sections of roll surface of the roller is connected with a connecting sleeve. The roller surface is inlaid in the connecting sleeve. The bearing and the bearing nut is fixed in the connecting sleeve outside the roller surface. The bearing coat is the connecting body that fixes the connection between the roll and the lead screw, the connecting body is fixed by the threaded sleeve, and the threaded sleeve interlinks both the obverse side and the reverse side of the lead screw. The motor drives the lead screw to rotate, the threaded sleeve moves horizontally, and the gap between the rollers is adjusted to satisfy the forming of the plates with different thickness and the square rectangular tubes with different sizes. The unit is used in the Hankou rolling mill of WISCO. When the size of the square rectangular tube changes, the adjustment is very convenient. Figure 6 is the structural description of this patent.

cold-bending-forming-unit-with-adjustable-roll-width

Figure 6. Cold Bending Forming Unit with Adjustable Roll Width

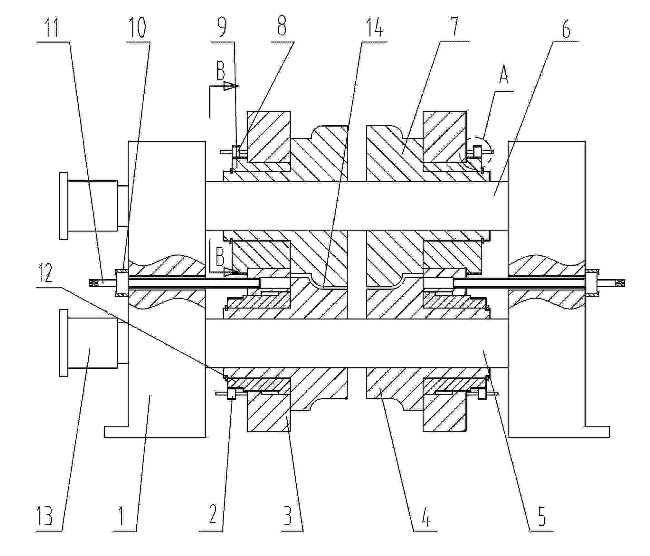

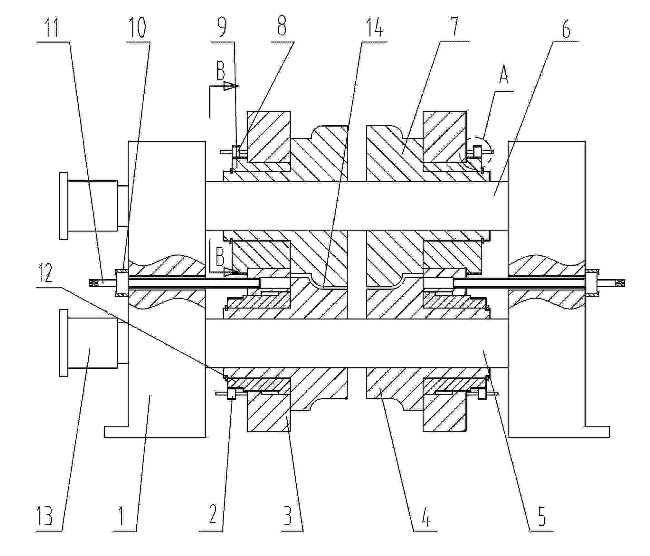

Through further development, the patent published a new rolling mill structure, especially a kind of floating archway rolling mill which is suitable for processing rolled pieces that have wide variation of the width. The upper and lower roll shafts between the two fixed archways correspond to the position of the rolled piece is mounted on the upper and lower roller floating archway equipment. The upper and lower roll floating archway equipment is composed of two sets of upper and lower roller floating mechanisms. Each upper and lower roller floating mechanism is composed of a floating archway, an eccentric sleeve, a gear that can adjust the center distance between the roller shafts, a lower roll sleeve, a gear that can adjust the lower roll axial and components that can adjust the width. It is suitable for the rolling of rolling pieces with wide variation in width and suitable for rolling small square rectangular tubes with large thickness. The structure of this patent is figure 7.

a-new-type-of-cold-bending-forming-unit-with-adjustable-roll-width

Figure 7. A new type of cold bending forming unit with adjustable roll width

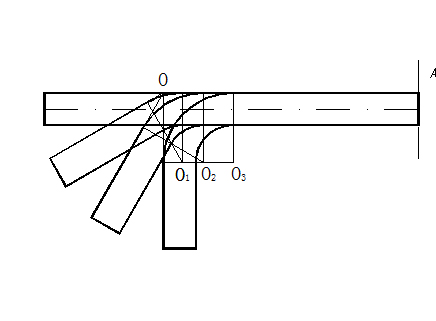

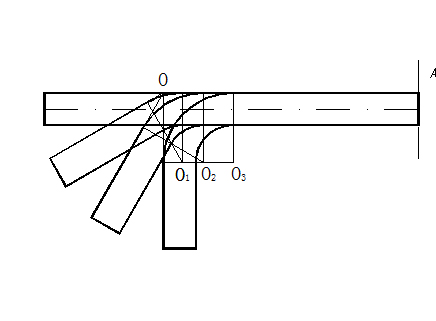

The existing design methods of cold bending include fixed length method (bending center up-shift method), fixed radius method (variable point fixed diameter method, bending center moving) and so on, which can not satisfy the requirement of the accurate bending of square rectangular tube when its thickness varies. The innovation of the rolling mill structure can meet the requirements of the size adjustment of square rectangular tubes with different specifications, as well as the adjustment of the gap of the upper and lower rollers for adapting to the thickness change of the plates. How to satisfy and realize the adjustment requirements of products with different sizes and different wall thickness from design methods has become an urgent problem to be solved. Professor Liu Jiying gives the bending design method in which the outer line contour is treated as the fixed intersection point. This method can satisfy the complete public use and high precision of the roll type and the method is also convenient for the servo adjustment of flexible roll type system.

the-bending-design-method-in-which-the-outer-line-contour-is-treated-as-the-fixed-intersection-point

Figure 8. The bending design method in which the outer line contour is treated as the fixed intersection point

With this design method, when the thickness of the plate changes, the thickness direction of the roll type is adjusted directly according to the plate thickness difference, and the axial direction can be adjusted according to the corresponding geometric relationship. The adjusted pass can achieve the accurate bending forming of sheet materials without any error in theory. When the plate thickness of the product changes, the vertical direction of the pass is adjusted according to the plate thickness difference, and the horizontal transverse direction is adjusted according to the geometric relationship between the bending angle and the thickness difference. The equipment of Italy STAM company can realize the forming of the plates with different thickness of 0.3-13mm. It solves the problem of accurate roll forming of rolls for public use under different plate thickness.

4.4 High-precision Square Rectangular Tube Inspection Technology

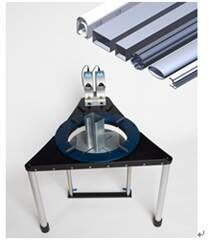

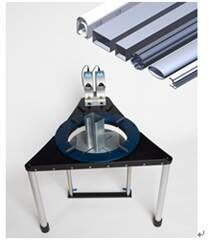

At present, as for the inspection of square rectangular tubes in the production process, common gauge calipers, micrometers and angle scales are adopted. For the measurement of rounded corners, section projection is needed. For cold bending section steel products, especially those with complex cutoff, desktop contour scanner is a convenient and quick detection tool. The COPRA® desktop contour scanner makes use of sensors and turntables to achieve the non-contact measurement of the section of the section materials. The system has high precision and flexibility. When measuring section materials, you only need to rotate the section material turntable by 360 degrees to get the scanning outline of the entire surface surface. Using software, the entire scanning section can be calibrated to a contour, and compared with the ideal design section, the deviation distribution of the surface can be quickly and accurately obtained, and determine whether or not the difference is exceeded.

copra-desktop-contour-scanner

Figure 10. COPRA® desktop contour scanner