|

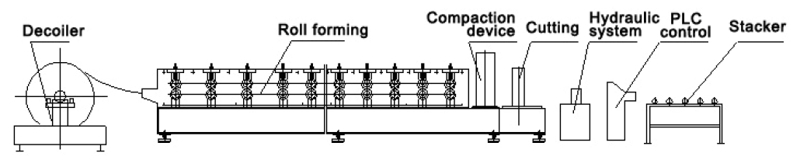

Decoiler / Uncoiler |

1 Unit |

|

Main Roll Forming Machine |

1 Unit |

|

Hydraulic Press Device |

1 Unit |

|

Hydraulic Cutting Device |

1 Unit |

|

Hydraulic Power Pack |

1 Unit |

|

PLC Computer Controller |

1 Unit |

|

Runout Table |

2 Units |

|

Name |

Item |

Description |

|

Roof Tile Roll Forming Machine |

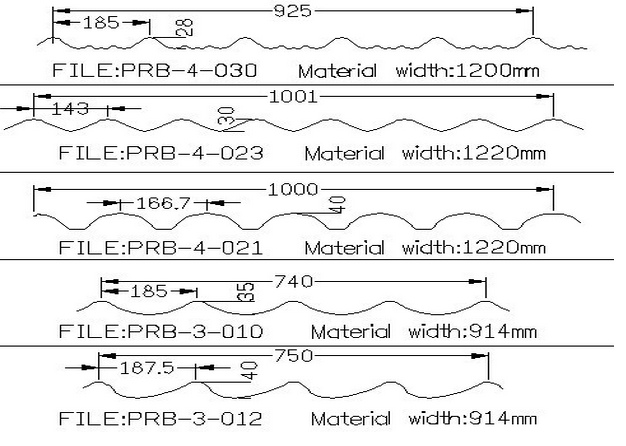

Production Material(mm) |

Thickness(0.3~0.8)×L, |

|

Number of stations |

18 stations |

|

|

Forming speed |

6-8 m/min |

|

|

Roller material |

GCr15 with heat treatment and |

|

|

Shaft diameter |

76mm |

|

|

Shaft material |

High-quality steel 45 quenched and |

|

|

Power of main motor |

7.5 KW |

|

|

Power of cutting motor |

5.5 KW |

|

|

Hydraulic Station Pressure |

10~15 Mpa |

|

|

Transmission device |

Chain drive |

|

|

Cutting |

Hydraulic cutting after formed |

|

|

Electronic controlling system |

Full-frequency PLC controlling system |

we will contact you within 24 hours.