Composition of Roof Decking Roll Forming Machine

Roll forming main machine…………………………….1 unit

8T manually de-coiler…………………………………….1 unit

Control panel…………………………………………...1 unit

Hydraulic station…………………………………… …1 unit

Manual out table………………………………… ……1 unit

Spare tools……………………………………………...one box

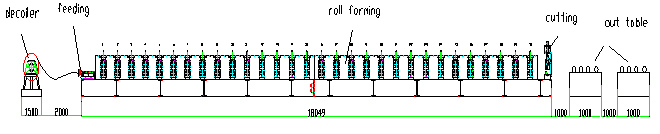

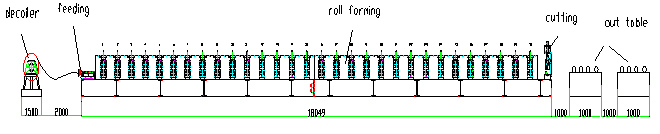

Forming Flow of Roof Deck Roll Forming Machine

Decoiling—feeding—guide----roll forming----cut to length—product packing manual

Working Flow Sketch of Roof Deck Roll Forming Machine

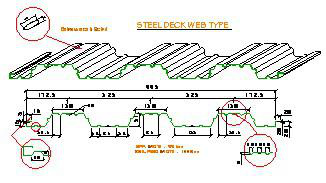

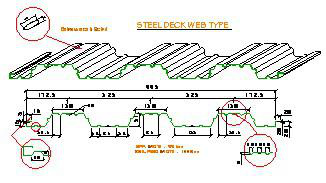

Steel Roof Decking Roll Forming Machine of Roof Deck Roll Forming Machine

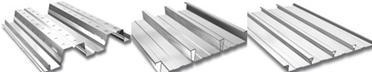

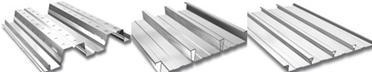

We can manufacture as per customer provided drawings or real objects of sectional materials, customization is welcome. The following are some floor decking panel profiles as a reference.

Applications of Roof Deck Roll Forming Machine

Applications of Roof Deck Roll Forming Machine

Steel Roof Deck sheets can be used as a composite floor system or as a permanent formwork. It binds with concrete slab and together forms a part of the floor structure. The interlocking between the concrete and the roof floor deck occurs by a system of embossment and ribs that are built into the deck, creating a reinforced concert slab. This fast and simple installation using high strength product gives immediate access to a working platform of permanent form and positive reinforcement. With its advantage, the steel roof deck is widely used various steel constructions

-

Versatility

-

Structural Strength with Less Weight

-

Attractive Appearance

-

All Weather Construction

-

Proven Durability

-

Economy and Value