The production lines for construction and building profiles consist of RISHBIN roll forming machines: the size and type of system are decided case by case on the basis of the profiles to be made.

The heavier building profiles such as the SIGMA, OMEGA, C and Z sections are often formed and punched holes.

With RISHBIN lines our customers use the parametric programming and the versatility of punching machines to pre-punch the coil before the forming process. In this way, the profiles come out of the machine already cut to size and with the holes in the exact position for the assembly and application of the fixing brackets.

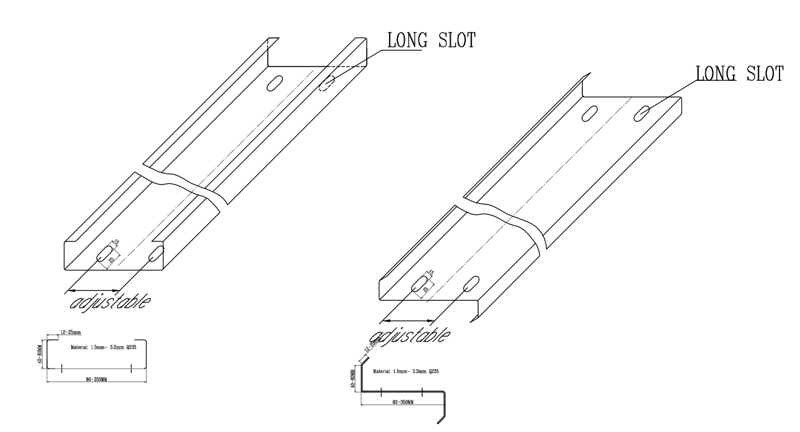

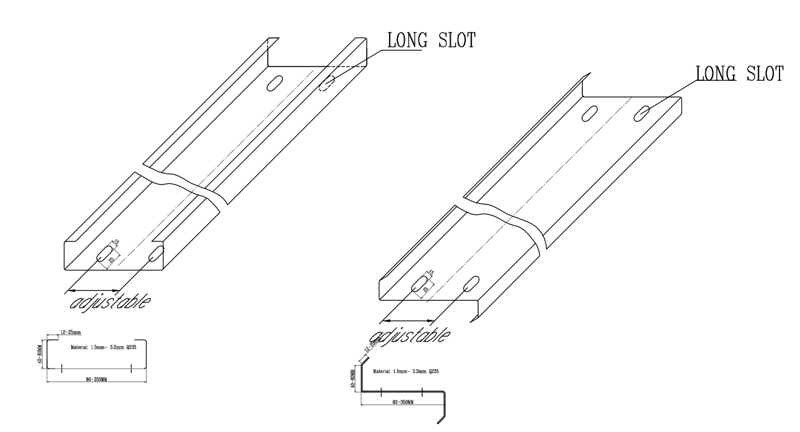

Production Characteristic and Use of Heave Gauge Purlin Roll Forming Machine

This heavy gauge purlin roll forming machine adopts new station to increase the firmness of machine; both chain drive and gearbox transmission are available; machine uses post cut to ensure the quality of cutting position of product very smooth; products are widely used in steel structure building.

Purlin Section Sizes of Heave Gauge Purlin Roll Forming Machine

Description of Heave Gauge Purlin Roll Forming Machine

1. By adjusting spacers, the heavy gauge purlin roll forming machine is able to produce six kinds of products with different specifications.

2. It adopts stepless variable speed drive, including the manual type and automatic type, to fabricate different purlins, ensuring high precision and stable performance.

3. According to the customer's requirements, there are three options for the production process

pre-punching and pre-cutting type (punching – cutting- pressing),

pre-punching and post-cutting type (punching – pressing - cutting),

post-punching and post cutting type (pressing – punching - cutting).

4. Our purlin roll forming machine can be designed according to the drawings and requirements provided by our client.

Components of the whole line

-

10T motorized decoiler with hydraulic expansion

-

Roll forming machine

-

Hydraulic shear without changing blades

-

Hydraulic station

-

Hydraulic punch system

-

PLC control cabinet

-

Run out table