|

Name |

Item |

Description |

|

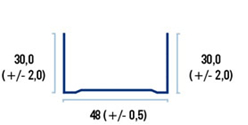

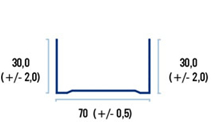

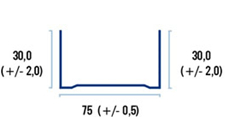

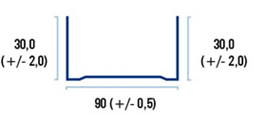

Drywall Stud Track Roll Forming Machine |

Production Material Thickness |

0.5mm-1.0mm |

|

Forming Speed |

8~15m/min |

|

|

Number of Stations |

10 stations |

|

|

Roller Material |

GCr15 with heat treatment |

|

|

Spindle Diameter |

70mm |

|

|

Spindle Material |

High-quality steel 45 quenched |

|

|

Power of Main Motor |

7.5 KW |

|

|

Power of Hydraulic Station |

3.0 KW |

|

|

Cutting |

Shear after formed |

|

|

Electronic Controlling System |

Full-frequency PLC controlling system |

|

|

Material of Cutting Blade |

Cr12 quenched |

we will contact you within 24 hours.