Quick Details

|

Production Capacity:

|

10-15m/min

|

Weight:

|

12.0T

|

|

Power(W):

|

29.5 KW

|

Cutting device:

|

hydraulic shearing 1 set

|

|

Voltage:

|

380V

|

Dimension(L*W*H):

|

10.5*1.3*1.5m

|

|

Certification:

|

CE and ISO

|

Warranty:

|

12 months

|

|

Control system:

|

PLC Yaskawa Inverter

|

Main motor power:

|

22 KW

|

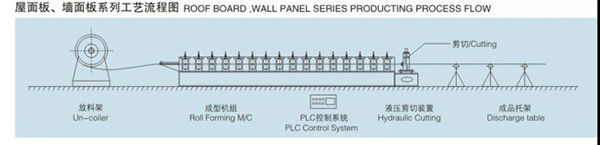

Technical Process of Comflor Deck Roll Forming Machine

Decoiling — feed-in (put steel coil into the first feeding roller) — leveling — roll forming — hydraulic shearing — run out table

Electrical Control System of Comflor Deck Roll Forming Machine

|

Screen display

|

5.7 inches Siemens

|

|

Computer control cabinet

|

It adopts industrial computer to control. Final product length is adjustable and digit of it can be adjusted. There are two modes: automatic and manual type. The system is easy to be operated and used.

Processing precision: within 1.00mm

It contains touch screen, PLC programmer and kits of every part.

Transducer brand is EURA

English language edition is available

|

Hydraulic Shearing of Comflor Deck Roll Forming Machine

|

Material of blade

|

Cr12 with heat treatment 60-62°C

|

|

Shearing system

|

It is controlled by gear wheel oil pump. After filling hydraulic oil into hydraulic oil tank, the pumps drive the cutter to start cutting job.

The system includes one set of hydraulic tank, one set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.

Power of oil pump: 5.5kw

Hydraulic oil: 40#

|

Applications of Comflor Deck Roll Forming Machine

Steeldeck sheets can be used as a composite floor system or as a permanent formwork. It binds with concrete slab and together forms a part of the floor structure. The interlocking between the concrete and floor deck occurs by a system of embossment and ribs that are built into the deck, creating a reinforced concert slab. This fast and simple installation using high strength product gives immediate access to a working platform of permanent form and positive reinforcement. With this advantage, the steel deck is widely used in various steel constructions

-

Versatility

-

Structural Strength with Less Weight

-

Attractive Appearance

-

All Weather Construction

-

Proven Durability

-

Economy and Value

Steel structural floor panel is the type of steel construction material with character of light weight, hard, easy to install, which extensively apply in constructing skyscraper, residential building and bridge. Our steel structural floor panel machine with its feature of reliable, convenient operation, automatic can be used in various steel structural floor panels forming.